Tagged: plywood

A fret saw jigsaw puzzle

While recently, in my mind, the word “jigsaw” has become more closely associated with the power tool, it nevertheless continues to remind me of the saw’s namesake puzzles. Des is no stranger to these, and takes justified pride in being able to put together puzzles intended for kids 2-3 years her senior. In light of that, the puzzle I made for her posed little challenge, but was still warmly received. Continue reading

Guess what this is going to be

Here’s something that’s been in the works for a few days:

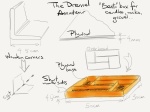

Made: Bento Box

Oof, this was a long one! I originally uploaded my blueprint for this thing at the beginning of January, then reported some progress two weeks ago, after which it stayed idle. The second delay was mostly due to a shortage of raw materials – something that took longer to rectify than expected.

Oof, this was a long one! I originally uploaded my blueprint for this thing at the beginning of January, then reported some progress two weeks ago, after which it stayed idle. The second delay was mostly due to a shortage of raw materials – something that took longer to rectify than expected.

I am glad that I decided to build this box since it, more than any other thing I’ve made so far, really made me stop rushing forward with a “close enough is good enough” attitude. I wrote about that lesson in the post On the Importance of Precision – that title really sums it up. Continue reading

“Frame” earring rack

My projects, it seems, come in groups. I started out with the Dremel 4000 by making a wooden ring and then went on to make two more in quick succession. More recently, I got going with the Bento Box and shortly after used the same mitre joining technique to make a kitchen tray. Today, I followed up on that with a third mitred frame, this one to serve as Mari’s earring rack.

My projects, it seems, come in groups. I started out with the Dremel 4000 by making a wooden ring and then went on to make two more in quick succession. More recently, I got going with the Bento Box and shortly after used the same mitre joining technique to make a kitchen tray. Today, I followed up on that with a third mitred frame, this one to serve as Mari’s earring rack.

The idea for this came from browsing Pinterest: there, someone had bought a picture frame, strung two or three lines of wire across it, and used those to hang necklaces and earrings. The only thing that was different about my version was that the frame was not store-bought but made out of 3.5cm-wide wooden corners: exactly the same approach as I used for the frame of the Bento Box. The frame is roughly 25 × 35 cm, with 45° cuts joined up to make square corners. The last two times I made mitred cuts, I did so with my own flimsy and undersized mitre box. This time, things went infinitely faster and smoother thanks to the fact that I had spent €9 on a mitre box / saw set.

Crack your knuckles, it’s finger joint time!

A finger (box) joint

After writing about mitre joints yesterday, I had a look at Wikipedia’s Woodworking joints page to educate myself a bit more. The dovetail joint, which I am still very keen to try, does seem to be rather advanced, as evidence by this quote:

…the cutting of dovetails by hand is regarded as a mark of skill on the part of the craftsperson.

So today, not being entirely confident in my masterful skills, I settled for the dovetail’s simpler counterpart – the finger joint. Also known as a box joint, thanks to its extensive use in boxes, drawers, etc., the finger joint aptly suits its name its name by resembling interlocked fingers of two hands.

The theory here is not overly complicated: sets of “fingers” are cut into the edges of the two abutting pieces, their depth corresponding to the material’s thickness. On one piece, the fingers are offset with respect to the other, so that the fingers “entwine” when the two pieces are put together. Continue reading

Quick weekend project: kitchen tray

A mitre joint

Saturday was cold, with the temperatures hovering below -20°C, so our little family hunkered down and stayed warm inside. Between doing some creative math with Des, watching a movie, enjoying Mari’s cooking, and taking a family nap, there was just enough time for me to make a little something for our kitchen. Until now, we’ve had our oil and vinegar bottles and other miscellany sit in an old shoe box lid on a kitchen counter. Replacing this storage solution with something a little nicer and sturdier has been on the “To Do” list for a while.

The half-finished Bento Box had given me a pretty good primer on making a rectangular frame, although this time everything was done with 4mm plywood. Unlike the Bento Box, the tray is long and narrow, over 60cm in length but only 20cm wide. Its sides are made out of 4.5cm-wide plywood strips that were fitted together with mitre joints. The same shaky little mitre box that I cobbled together a week ago, and almost threw out right after, came in very handy for cutting the 45° angles with a utility saw, though once again the 4.5cm plywood pieces were too tall for it and I had to eyeball the initial portion of every cut. Nevertheless, the final fit of the tray’s sides was pretty darn good. Continue reading

Yup, there’s yer problem!

Things have been a bit slow around here for the past couple of days. I ran out of raw material to finish the Bento Box, so it is lingering in a half-done state. Mari has just a few minutes ago commandeered it for “temporary” use as a tray for candles and other miscellany, and I have a shadow of a doubt as to whether it will ever become the originally-intended final product. Time will tell. I’ve also done one or two things in Des’s café, but they are too small to be honoured with a full post.

So, tonight, with only a little free time, no new ideas for another Blueprint, and nothing but plywood on hand, I took a few minutes to practice my sawing technique. On a strip of plywood around 4cm wide, I marked out 8 cuts 1cm apart and got to work with the jigsaw: Continue reading

Movable parts? You better believe it!

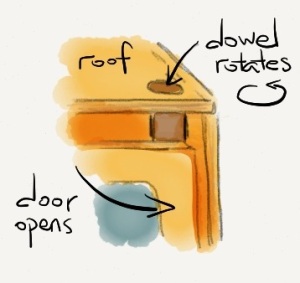

The refrigerator’s two doors would be attached to rotating dowels. Made with Paper

When the Hello Kitty café was finished, Des did a very good job of hiding her disappointment at the fact that the refrigerator’s doors didn’t open. While this wasn’t high on my list of things to do for the café, or in general, somehow Sunday morning found me pondering how to make it happen.

In my original café blueprint, I had an idea for making a swing door for the kitchen’s entrance, but I suspected that in this case that solution would tend to keep the fridge doors permanently open – no good. I briefly considered using small brad nails as pivots but, upon remembering my one attempt to hammer those into 4mm-thick plywood, that idea was discarded as well. Then, quite by chance, my glance fell on the 10mm wooden dowel and a new plan was born: I would attach the fridge doors to dowels, which would be inserted into holes in the fridge’s roof and floor. This way, the whole door / dowel assembly could rotate, with the dowel acting as the axis.

Without thinking ahead, I placed the dowel holes right next to the fridge’s walls, and paid for it later. Continue reading

On the importance of precision

On Saturday, I started working on the Bento Box / Zen Garden. By evening, I got as far as finishing the tray box. It was a long day.

On Saturday, I started working on the Bento Box / Zen Garden. By evening, I got as far as finishing the tray box. It was a long day.

I mentioned before that my work has been suffering from unintentional sloppiness – crooked cuts, imprecise sanding angles, etc. Luckily or, perhaps, unluckily, I have been getting away with it on the small scale of the Hello Kitty café furniture – the tables and countertops were OK without perfect corners or balance, and glue held everything together in the end. This by-the-seat-of-my-pants approach came to a screeching halt with the Bento Box.

I started making the frame out of the 4.5cm-wide wooden corners, measuring two 30cm and two 50cm pieces. To join them at the corners, I wanted to make all cuts at 45° angles – a classic fit seen in most picture, window etc. frames. I vaguely remembered seeing sawing guides for cutting at an angle, but thought that I could do without. The protractor imprinted into the tabletop of my workbench is not particularly useful, and so I resorted to basic geometry: measure e.g. 2cm in one direction, measure 2cm perpendicular to the first, draw a diagonal by joining the two measures, and you’re good to go, right?

Hello Kitty café: Table #3

In the ongoing “table-a-day” category, here’s table #3 for Des’s café.

The evening began with Des, Mari and I making miniature food and accessories for the café out of FIMO clay. Our efforts were pretty impressive for beginners, and they’ll be definitely showcased sometime in the near future. While the clay was baking, I went back to the workbench to make another table. Once again, the overall shape and size were to remain the same: the round table top was made according to the same 11cm coffee cup, and the height of the legs was to be 8cm, as with tables 1 and 2.

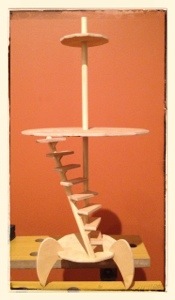

I had an idea for the table’s legs, but at the last minute something just didn’t feel right, and I searched for an alternative. On Mari’s suggestion, I took a look at the 1cm wooden dowel, of which quite a bit still remained after I had last used it for the pen rack. A new design was born: the dowel would serve as the single central table leg. At the bottom, it would be joined by 3 small plywood feed that would give it stability. Overall, a pretty classic design for a café / diner table. Continue reading