Category: Technique

Yup, there’s yer problem!

Things have been a bit slow around here for the past couple of days. I ran out of raw material to finish the Bento Box, so it is lingering in a half-done state. Mari has just a few minutes ago commandeered it for “temporary” use as a tray for candles and other miscellany, and I have a shadow of a doubt as to whether it will ever become the originally-intended final product. Time will tell. I’ve also done one or two things in Des’s café, but they are too small to be honoured with a full post.

So, tonight, with only a little free time, no new ideas for another Blueprint, and nothing but plywood on hand, I took a few minutes to practice my sawing technique. On a strip of plywood around 4cm wide, I marked out 8 cuts 1cm apart and got to work with the jigsaw: Continue reading

Movable parts? You better believe it!

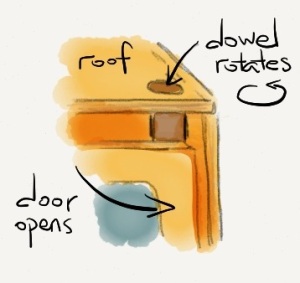

The refrigerator’s two doors would be attached to rotating dowels. Made with Paper

When the Hello Kitty café was finished, Des did a very good job of hiding her disappointment at the fact that the refrigerator’s doors didn’t open. While this wasn’t high on my list of things to do for the café, or in general, somehow Sunday morning found me pondering how to make it happen.

In my original café blueprint, I had an idea for making a swing door for the kitchen’s entrance, but I suspected that in this case that solution would tend to keep the fridge doors permanently open – no good. I briefly considered using small brad nails as pivots but, upon remembering my one attempt to hammer those into 4mm-thick plywood, that idea was discarded as well. Then, quite by chance, my glance fell on the 10mm wooden dowel and a new plan was born: I would attach the fridge doors to dowels, which would be inserted into holes in the fridge’s roof and floor. This way, the whole door / dowel assembly could rotate, with the dowel acting as the axis.

Without thinking ahead, I placed the dowel holes right next to the fridge’s walls, and paid for it later. Continue reading

On the importance of precision

On Saturday, I started working on the Bento Box / Zen Garden. By evening, I got as far as finishing the tray box. It was a long day.

On Saturday, I started working on the Bento Box / Zen Garden. By evening, I got as far as finishing the tray box. It was a long day.

I mentioned before that my work has been suffering from unintentional sloppiness – crooked cuts, imprecise sanding angles, etc. Luckily or, perhaps, unluckily, I have been getting away with it on the small scale of the Hello Kitty café furniture – the tables and countertops were OK without perfect corners or balance, and glue held everything together in the end. This by-the-seat-of-my-pants approach came to a screeching halt with the Bento Box.

I started making the frame out of the 4.5cm-wide wooden corners, measuring two 30cm and two 50cm pieces. To join them at the corners, I wanted to make all cuts at 45° angles – a classic fit seen in most picture, window etc. frames. I vaguely remembered seeing sawing guides for cutting at an angle, but thought that I could do without. The protractor imprinted into the tabletop of my workbench is not particularly useful, and so I resorted to basic geometry: measure e.g. 2cm in one direction, measure 2cm perpendicular to the first, draw a diagonal by joining the two measures, and you’re good to go, right?